Lithium ion batteries are widely used in the new energy industry because of their high energy density and long cycle life. However, due to a series of irreversible physical and chemical reactions, such as lithium ion deposition, loss of active materials and so on, the cycle life of lithium-ion batteries is deteriorating. Battery health state (soh) is a judgment index of battery cycle life. From the perspective of safety, the SOH generally drops to 70% - 80%, which means that the battery needs to be replaced in time.

Since the traditional BMS can only monitor a limited number of parameters such as the voltage, temperature and current of the battery, the current SOH value is usually estimated online in the industry in the following ways:

SOH = current maximum dischargable capacity (SOC) / rated capacity value of the battery at delivery

In the laboratory or factory, the SOH of the battery can also be estimated through internal resistance monitoring by means of electrochemical workstation and other equipment:

SOH = (internal resistance at the end of battery life current internal resistance) / (internal resistance at the end of battery life factory internal resistance)

Because the estimation of SOC is affected by many factors, and at least one complete charge and discharge cycle is required to estimate the current SOC, the estimation accuracy of SOH is difficult to guarantee and cannot be directly obtained. However, the on-line detection cannot be realized by means of electrochemical workstation and other equipment. Therefore, SOH estimation has always been a technical difficulty in BMS development. We need a fast and reliable method to online monitor the "state of health" (soh) of lithium-ion batteries, which is also a hot topic in battery research.

Flexible innovation

This paper will introduce an original online SOH monitoring technology. We know that the increase of the internal resistance of the battery is an important manifestation of the battery aging and the reason for the further aging of the battery. The internal resistance of the battery can be analyzed by electrochemical impedance spectroscopy (EIS), which can give a more detailed description of the battery impedance and can be used to estimate the life characteristics of the battery. In the past, monitoring the EIS characteristics of batteries can only be realized in the laboratory with the help of electrochemical workstation and other equipment, and online monitoring cannot be realized. The integrated EIS monitoring single cell monitoring chip dnb1168 launched by Datang NXP can easily realize real-time online SOH monitoring through online impedance monitoring technology.

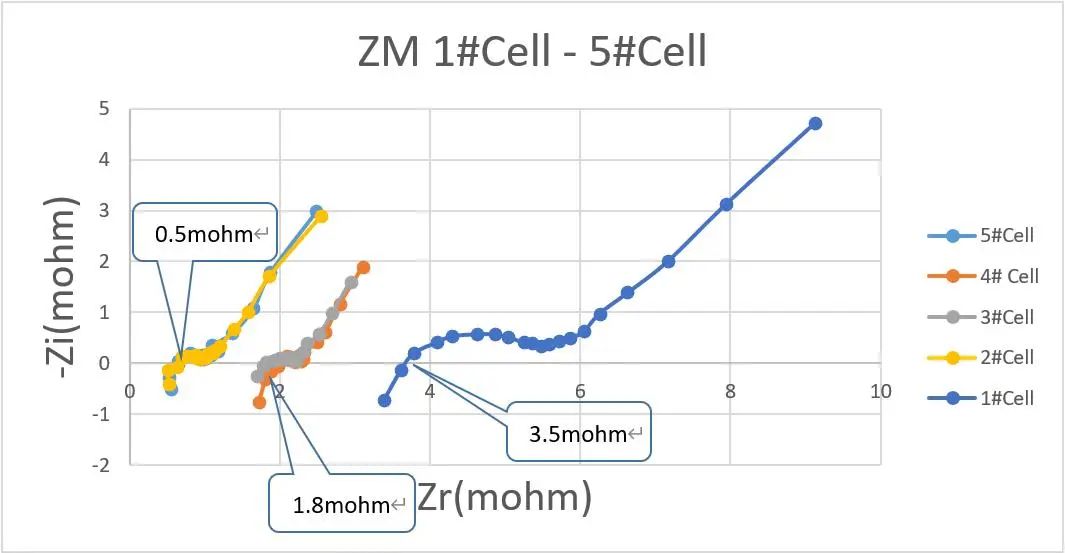

Here is a real case to illustrate how to use dnb1168 chip to realize online SOH monitoring through EIS. First, we conducted EIS calibration for five batteries with different SOH states under the same capacity and temperature. The calibration results are shown in the figure.

EIS monitoring data of batteries 1-5

The ohmic impedance value of No. 2 and No. 5 batteries was 0.5 milliohm and the true SOH was 100%. The No. 3 and No. 4 batteries were 1.8 milliohms and the true SOH was 85%. The No. 1 battery is 3.5 milliohms and the true SOH is 70%. According to the previous formula for calculating SOH, we substitute the internal resistance values of SOH = 70% and SOH = 100% into the formula:

70% = (internal resistance at the end of battery life - 3.5) / (internal resistance at the end of battery life - 0.5)

It can be calculated that the internal resistance at the end of the battery life (soh = 0%) is about 10.5 milliohms, and the SOH = (10.5-1.8) / (10.5-0.5) = 87% when the internal resistance of 1.8 milliohms is calculated. The error with the real SOH is 2%, which is much higher than the SOH estimation level of the industry through capacity.

According to our experimental results, if the impedance of different SOH cells is calibrated in the early stage, the current SOH of the cell can be quickly reflected by EIS. Through the integrated EIS single cell monitoring chip dnb1168, the current health status of the battery can be easily monitored online.

The traditional SOH evaluation method involves capacity calibration using low rate charge / discharge method, which is time-consuming, power consuming, low precision, high cost and impractical. EIS has the advantages of low cost, easy implementation and high estimation accuracy.

More BMS innovations are coming

Through continuous innovation in the battery management system, we can help manufacturers maintain the safety of solutions in applications such as electric vehicles and industrial energy storage, while reducing design complexity and thus reducing costs. Each generation of innovation is based on the previous generation of innovation, making our technology more flexible, efficient, reliable and affordable. We will unswervingly carry out technological innovation, grow and progress with end customers, and strive to achieve real localization.