Datang NXP Semiconductor Co., Ltd

Awarded the honor of "2023 China's Most Valuable Investment Vehicle Class Chip Enterprise"

On August 10, 2023, the 2023 China Automotive Semiconductor New Ecology Forum and the Fifth the Taihu Lake Lake Innovation Summit hosted by Binhu District Government of Wuxi City and the Municipal Bureau of Industry and Information Technology were held in Wuxi.

On the same day, the "Integrated Circuit Industry Education Integration and Talent Training Base" in Binhu District was successfully unveiled, and the "2023 Global Intelligent Vehicle Industry Atlas and Research Report" was released simultaneously.

During this period, under the guidance of the Wuxi Institute of Integrated Circuits, after strict evaluation by an expert group, the "Core List • Core Future 2023 China's Most Valuable Automotive Chip Enterprises" list was jointly released by the Asia Pacific Core Valley Technology Research Institute. As a pioneer in domestic semiconductor innovation, Datang NXP Semiconductor Co., Ltd. was awarded this honor!

Datang NXP, General Manager Chen, delivered an important speech

Mr. Chen Jian, Deputy General Manager of Datang Enzhipu, was invited to attend this conference and delivered a wonderful speech titled "New Energy Vehicle Battery Management Chip" around the theme of the conference "Chain Gathering Core Energy, Smart Creating the Future", detailing the super performance and unparalleled commercial value of DNB11 series chips.

1.【Innovate and move forward】 Helping China Chip Go Global

Datang NXP(Da'en Xinyuan) has been deeply involved in the field of new energy vehicles and energy storage for many years. Its business is positioned in battery management, motor drive, and related integrated circuit design for new energy vehicles. It focuses on the research and development and sales of advanced specialized automotive electronic chips using high-performance mixed signal technology, and is committed to becoming a leading automotive semiconductor company worldwide.

Automotive lighting

Datang NXP(Da'en Xinyuan) also has a driver chip product line for automotive lighting applications. The cumulative shipment volume exceeds 600 million pieces, ranking first in market share over the years!

Battery management chip AFE

With exclusive product technology that has been leading the market for 3-5 years, we have independently developed DNB series BMS AFE products that have passed multiple vehicle specification level certifications. Currently, they have been mass-produced, with customer orders exceeding nearly a million levels. They have successfully achieved commercial use in the fields of new energy and industrial energy storage, and have received high praise from customers.

Vehicle specification level design, manufacturing, certification

l The company has a technical team with rich experience in the research and development of car specification chips.

l With four core IP groups and product family development platforms, we have obtained nearly a hundred innovative patents.

l Meet the requirements of automotive grade wafer manufacturing and testing (IATF16949).

l DNB1101/DNB1168 have both passed the vehicle specification level AEC-Q100 product certification.

l DNB1168 has passed the highest functional safety level ISO26262:2018 ASIL-D certification in the automotive industry.

2.【Global Exclusive】Online CT detection technology for batteries

EIS Function Introduction

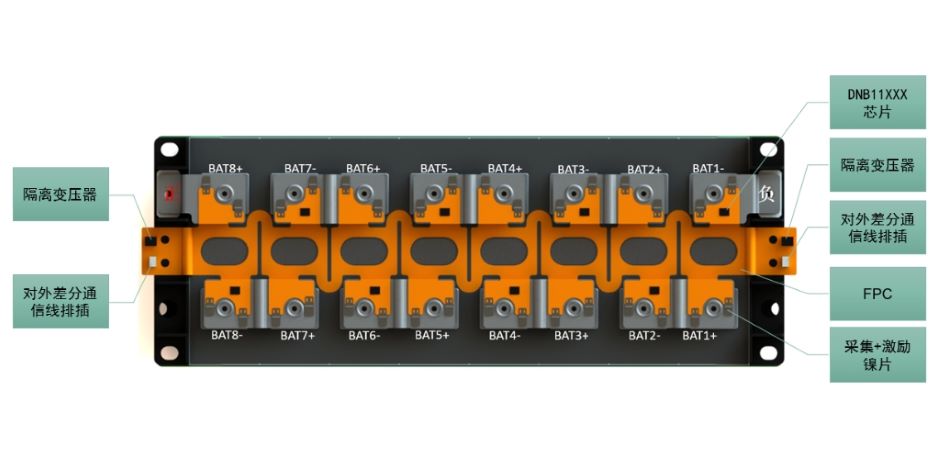

As the core business of the company, the DNB11 series AFE chips have innovative and disruptive significance. This series of chips is the only single battery monitoring chip in the world that can integrate (EIS) AC impedance spectrum monitoring function.

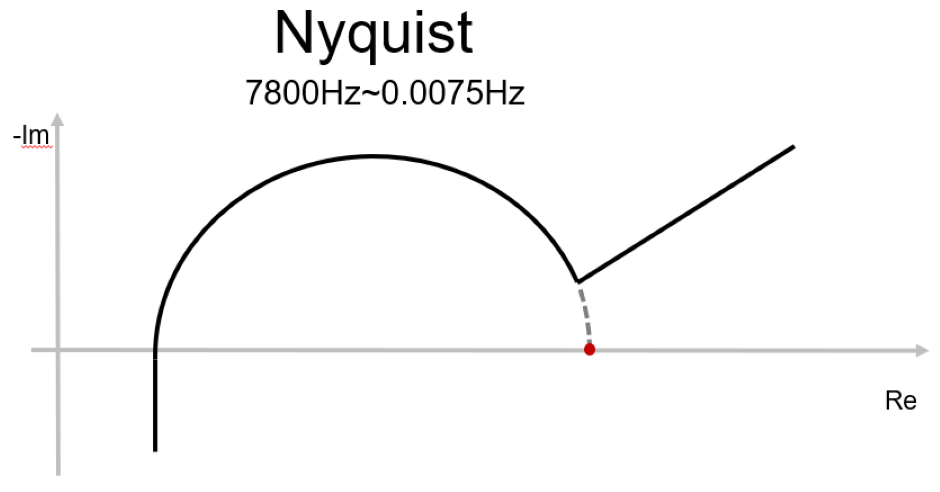

EIS (Electrical Impedance Spectroscopy) detection technology applies a certain frequency of current excitation to both ends of the battery electrode, collects voltage fluctuations at corresponding frequencies at both ends of the battery, and through digital processing, obtains the AC impedance of the battery at that frequency. The AC impedance at different frequencies is plotted as an EIS diagram, making the battery situation clear at a glance. EIS can detect the true electrochemical reactions inside the battery, which is equivalent to conducting a safe "CT" inspection of the battery, hence the name "Battery Online CT Detection Technology".

At present, the most common EIS equipment is an electrochemical workstation worth hundreds of thousands of yuan, but it is only used in the laboratory and cannot be applied online in the automotive/energy storage field. Datang Enzhipu Semiconductor creatively integrated the EIS function onto a battery management chip half the size of a nail cover, successfully achieving online application of this function in both vehicle and energy storage.

he installation of EIS technology on AFE chips is equivalent to the ability of cars to predict battery risks in advance, which can effectively solve battery safety pain points in the trend of new energy, fundamentally reduce the occurrence of problematic batteries, and minimize safety risks.

Unlimited commercial value of DNB11 series chips

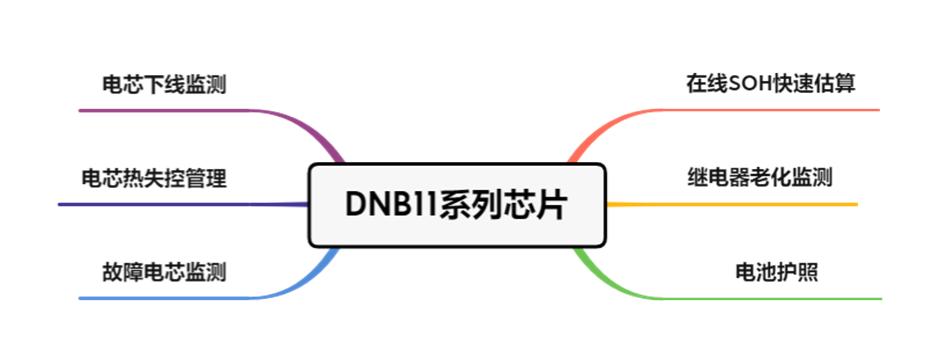

Cell offline monitoring

As a protective measure before the battery leaves the factory, offline screening of battery cell production is crucial. A system can simultaneously screen hundreds of battery cells, helping customers achieve better battery cell quality control. Replacing electrochemical workstations with chips achieves unparalleled economy in electrochemical workstations.

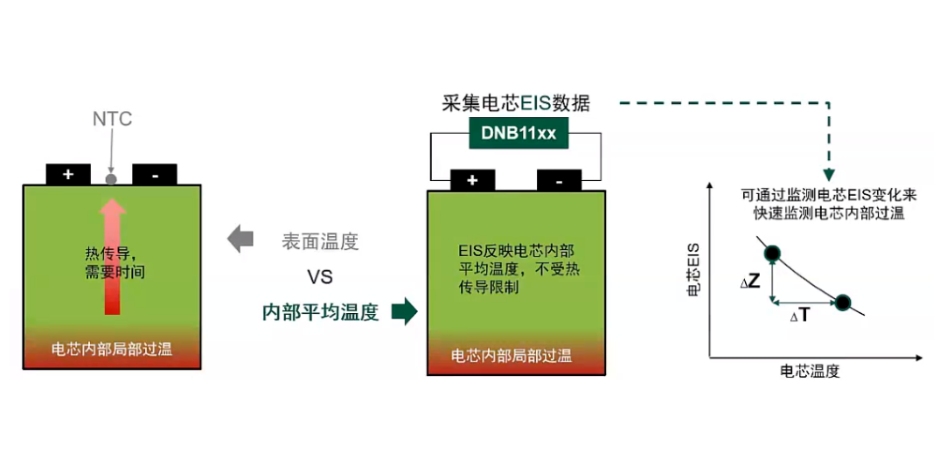

Thermal runaway management of battery cells

When there is a violent reaction inside the battery cell, the internal temperature will be significantly higher than the external temperature, and the larger the temperature difference, the greater the risk of thermal runaway. The internal temperature of the battery based on internal resistance estimation is faster and more accurate compared to the external NTC detection method, which can suppress the thermal runaway of the battery in the early stage and effectively solve the problem of detecting the thermal runaway of the battery cell, ensuring the safety of the entire life cycle of the new energy system.

Fault cell monitoring

We use our unique online impedance detection technology to perform horizontal outlier comparison on cells within a module or the entire pack. Impedance based outlier detection can quickly locate abnormal cells, accurately determine the cause of the abnormality, and screen out abnormal cells in a timely manner.

Online SOH fast estimation

The battery health status (SOH), as an important indicator of whether the battery can continue to be safely used, is the most important function in the battery management system. The DNB11 series chips with integrated EIS functions can achieve the integration of electrochemical workstations under laboratory conditions into the pack, thus achieving true SOH estimation based on the aging degree of the internal mechanism of the cell. Compared to the rough estimation method based on capacity, our solution has a disruptive advantage.

Relay aging monitoring

The cost of the detection circuit is low, the detection circuit is safe and reliable, and the detection data can be transmitted to BMS in real-time, accurately estimating the service life of the relay, and accurately detecting the aging conditions of the relay such as ablation, oxidation, adhesion, etc.

Battery passport

According to the EU's New Battery Law, future power and industrial batteries must have a carbon footprint declaration and label, as well as a digital battery passport, in order to enter the EU market. The DNB11 series of chips can be embedded into the battery during the production phase, recording a series of battery related parameters and unique information such as electrochemical composition and manufacturing information, achieving health management and carbon footprint tracking throughout the battery's entire life cycle.

Wireless BMS remote diagnosis

The DNB11 series chips are more flexible in adapting to future wireless BMS solutions, monitoring the health of each battery cell throughout its lifecycle, and reporting to individual users and data centers.

The battery CT detection technology of Datang NXP(Datang Xinyuan) has started the global commercialization process, and the business radiation scope will be more extensive in the future. We will actively create a more diverse and diverse enterprise core, by adhering to technological innovation, breaking through industry barriers, and creating more innovative, high-quality, and efficient solutions, to provide global customers with safer and more advanced extreme chip products, meet their different needs in different scenarios, promote the progress and upgrading of new energy battery technology safety management, and comprehensively promote the localization of core devices!