Heavyweight official announcement! DNB series battery management AFE chips achieve large-scale commercial use!

Datang NXP - Innovation Chronicle

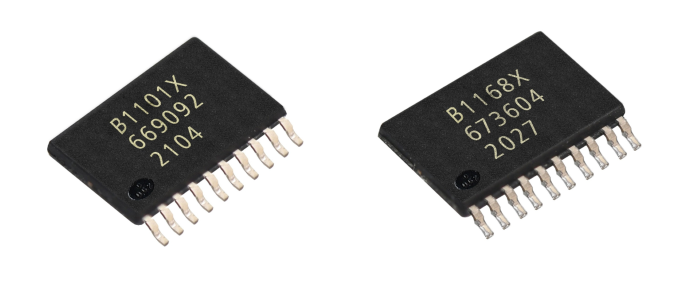

The Datang NXP team has been dedicated to research and development for many years, making innovative breakthroughs, and in 2022, the industrial version of the battery management chip DNB1101 was officially mass-produced. This year, our car grade battery management chip DNB1168 has officially been put into mass production! At the same time, we have exceeded nearly a million customer orders, which also means that online CT testing technology for batteries is moving towards commercialization on a large scale!

The release of Datang NXP flagship product DNB1168 is not only a major innovation in chip technology, but also a solid umbrella for the protection of automotive power batteries; For domestically produced BMS chips, while improving the dual industry standards at home and abroad, it also has extraordinary significance in accelerating the process of localization of core devices!

Small Chips • Big Wisdom

DNB1168 is a disruptive and innovative single cell lithium-ion battery monitoring chip that can provide electrochemical impedance spectroscopy testing for individual cells or parallel battery packs. And it has passed the ASIL-D certification, the highest functional safety level in the automotive industry.

This not only signifies that the device has reached an international leading level in terms of safety, but also means that it can fully meet the most stringent functional safety scenario research and development needs of the automotive industry. Can effectively help new energy vehicle manufacturers build safer and more efficient battery management systems.

At the same time, it has broken the situation where domestic BMS chips have always been highly dependent on imports, which has a milestone significance for the entire domestic BMS chip industry, marking that Datang NXP has the strength to compete with top international chip manufacturers on the AFE segment track.

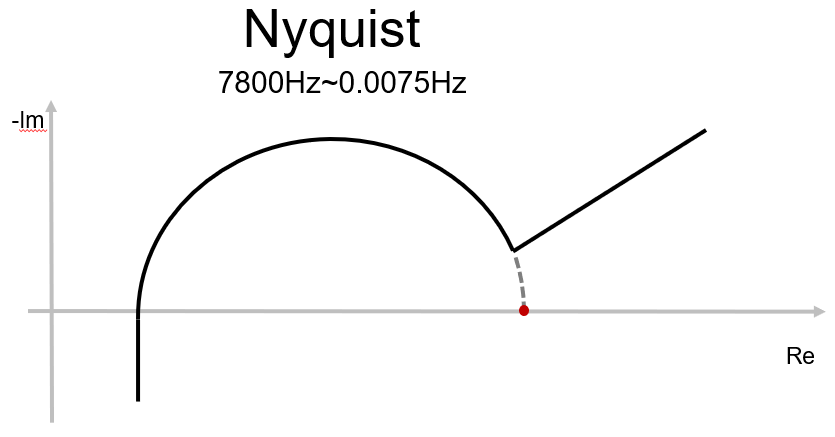

EIS impedance monitoring function

The online "CT" detection technology for batteries, also known as EIS (Electrical Impedance Spectroscopy) technology, is to apply a certain frequency of current excitation to both ends of the battery electrodes, collect voltage fluctuations at corresponding frequencies at both ends of the battery, and through digital processing, obtain the AC impedance of the battery at that frequency. The AC impedance at different frequencies is plotted as an EIS diagram, making the battery situation clear at a glance. EIS can detect the true electrochemical reactions inside the battery, which is equivalent to conducting a safe "CT" examination of the battery, hence its name.

At present, the most common EIS equipment is an electrochemical workstation worth hundreds of thousands of yuan, but it is only used in the laboratory and cannot be applied online in the automotive/energy storage field. Datang NXP Semiconductor creatively integrated the EIS function onto a battery management chip half the size of a nail cover, successfully achieving online application of this function in both vehicle and energy storage.

The installation of EIS technology on AFE chips is equivalent to the ability of cars to predict battery risks in advance, which can effectively solve battery safety pain points in the trend of new energy, fundamentally reduce the occurrence of problematic batteries, and minimize safety risks.

Unlimited commercial value of DNB series chips

1. Cell offline monitoring

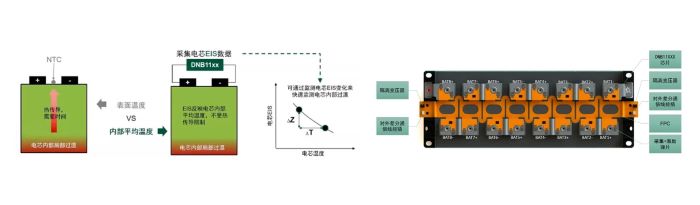

A system can simultaneously screen hundreds of battery cells, helping customers achieve better battery cell quality control. Replacing electrochemical workstations with chips achieves unparalleled economy in electrochemical workstations.

2. Thermal runaway management of battery cells

When there is a violent reaction inside the battery cell, the internal temperature will be significantly higher than the external temperature, and the larger the temperature difference, the greater the risk of thermal runaway. The internal temperature of the battery based on internal resistance estimation is faster and more accurate than the external NTC detection method, which can suppress the thermal runaway of the battery in the early stage and effectively solve the problem of detecting the thermal runaway of the battery cell, ensuring the safety of the entire life cycle of the new energy system.

3. Fault cell monitoring

We use our unique online impedance detection technology to perform horizontal outlier comparison on cells within a module or the entire pack. Impedance based outlier detection can quickly locate abnormal cells, accurately determine the cause of the abnormality, and screen out abnormal cells in a timely manner.

4. Online SOH fast estimation

The DNB series chip with integrated EIS function can achieve the integration of electrochemical workstation functions in the pack, which is limited to laboratory conditions at present, thus achieving true SOH estimation based on the aging degree of the internal mechanism of the cell. Compared to the rough estimation method based on capacity, our solution has a disruptive advantage.

5. Relay aging monitoring

The cost of the detection circuit is low, the detection circuit is safe and reliable, and the detection data can be transmitted to BMS in real-time, accurately estimating the service life of the relay, and accurately detecting the aging conditions of the relay such as ablation, oxidation, adhesion, etc.

6. Battery passport

According to the EU's New Battery Law, future power and industrial batteries must have a carbon footprint declaration and label, as well as a digital battery passport, in order to enter the EU market. Datang NXP DNB series AFE chips can be embedded in the battery during the production phase, recording a series of battery related parameters and unique information such as electrochemical composition and manufacturing information, achieving health management and carbon footprint tracking throughout the battery's entire life cycle.

Based on the present and looking forward to the future

Datang NXP will never stop innovating and creating excellence, developing products with market core competitiveness IP. We will continue to delve deeply into the field of new energy vehicles and energy storage, break industry barriers with leading technologies, provide more suitable solutions, and innovate business models; To provide global customers with safer and more advanced extreme products, meet their different needs in different scenarios, and promote the progress and upgrading of new energy battery technology safety management; Continuously striving to assist in the localization of core devices!